AQUAMAX ® PRO XXL - the SBR wastewater treatment plant for big challenges

Everything is possible with this wastewater treatment plant

- The individually planned SBR wastewater treatment system for industry, tourism and municipal applications.

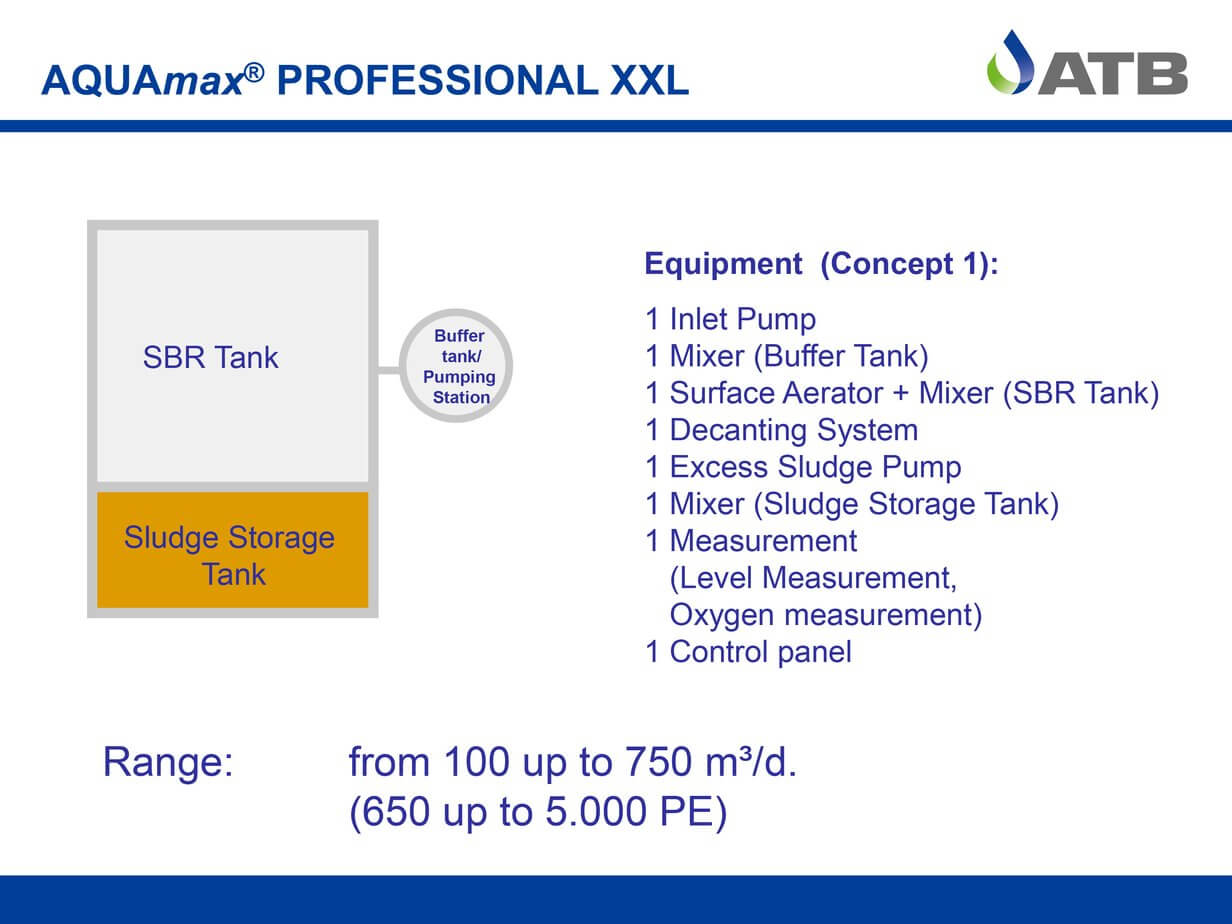

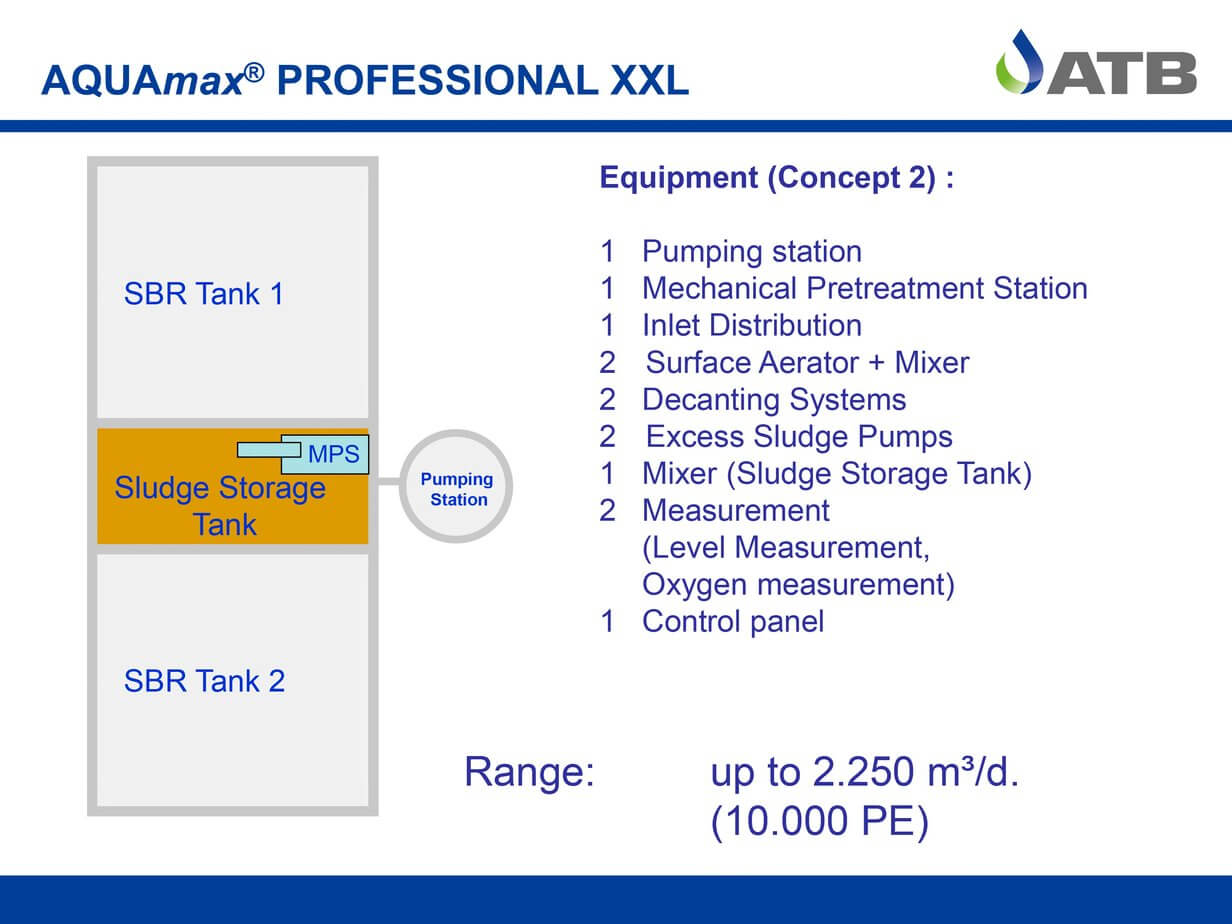

- Our wastewater treatment plant, individually for up to 10,000 PE or up to 1,500 m3/day

- Especially for fluctuating wastewater flows such as medium to large businesses or municipal applications

In addition to our standard range of wastewater treatment plants with a connected load of up to 1,000 PE, we offer tailor-made solutions for small and medium-sized municipal applications. We see ourselves in this area as a product-independent planning and construction company for wastewater treatment plants with a capacity of up to 10,000 PE or 1,500 m3/day.

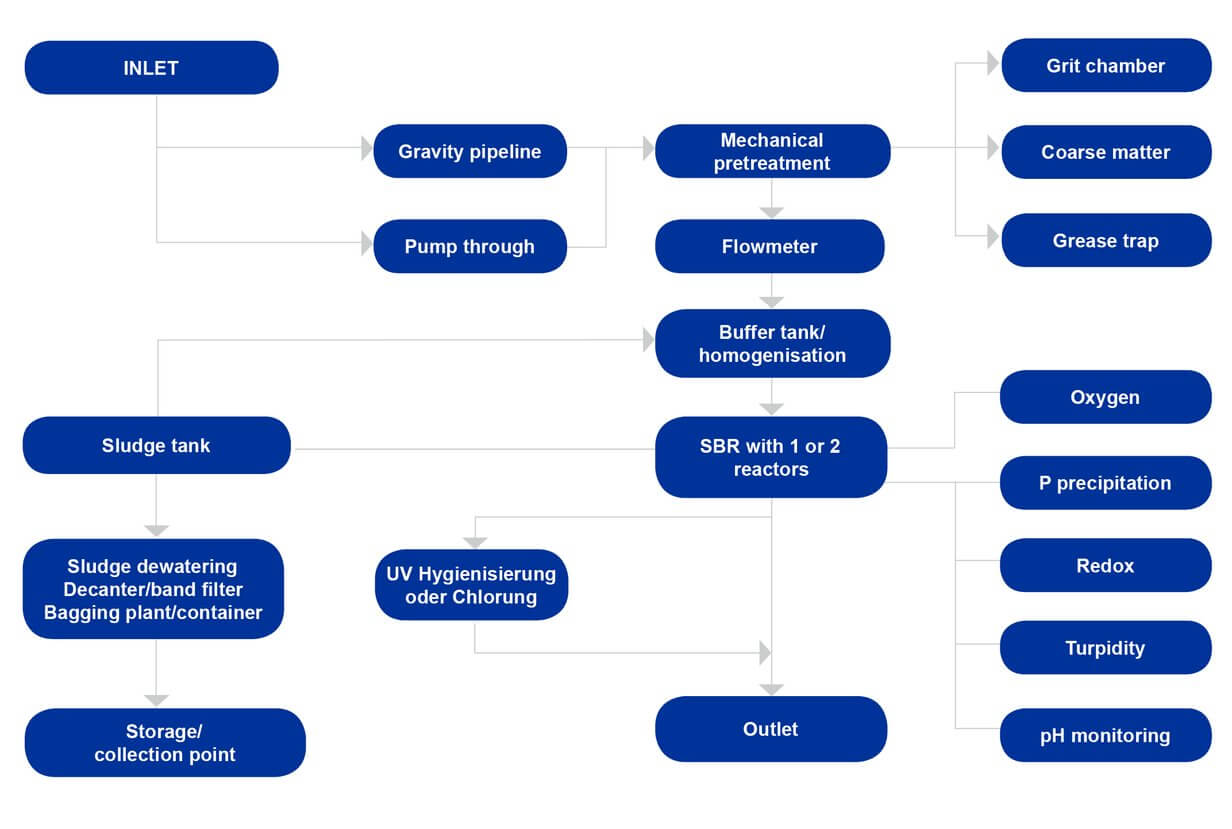

Our service and scope of supply includes all steps, from the process engineering concept of the wastewater treatment plant to the complete technical dimensioning of all components of the wastewater treatment plant - from the feed pump station, via the mechanical pre-treatment, the biological treatment stage, to the treatment of the excess sludge. The procurement of all components and materials from our subcontractors, the in-house engineering and production of the plant control, the detailed control and preparation of all goods before delivery, as well as a well prepared documentation and assembly on site, worldwide, completes our package.

Individual solutions for your application

There are no ready-made individual solutions. That's why we work with you to find the optimum solution for your wastewater treatment. Every construction of a wastewater treatment plant is preceded by a whole series of planning works. The better this preliminary work is carried out, the more efficiently the plant can be designed, planned and implemented.

For larger projects, our PRO team with its comprehensive services will be at your side from the very beginning and will support you far beyond the completion of the plant. Of course, at the beginning of every new wastewater treatment plant there is always the question: "What exactly should be built? But before an answer can be given, there are a number of other questions, that must first be answered in order to determine the current situation.

Survey

At a site visit, we determine the condition on site and clarify what is important: plant location, pipe routing, peripheral equipment to be installed upstream, any existing tanks, type and quantity of inflow water, requirements for the outflow water, requirements for discharge and much more ...

Conceptual approaches

Once all the relevant information has been evaluated, we create various alternative concept approaches based on your individual circumstances, all of which are capable of achieving the goals you have set - each in its own way. After all, "many roads lead to Rome...".

Together to the solution

These solution approaches form the basis for the development of the optimal solution. In one or more discussions with you, the different options are discussed, the respective pros and cons are weighed against each other and cost/benefit effects are compared. And at some point it will finally come to pass: the concept for your wastewater treatment plant.

Convince others

Often others have a say as well. Also in such cases, our PRO team is on the spot: We present the completely developed concept to the decision-makers and explain convincingly and in all details the developed solution - no matter if it is a citizens' meeting, an association, an authority or a company decision-maker.

Here we go!

Once this hurdle has also been cleared, we really get going: The final design of the plant is worked out, planning and approval documents are prepared, explanatory reports are written and, if necessary, tender texts are drafted. If further components such as grease separators, screen screws or screens are required, we will also take care of them and help you select the best peripherals. Of course, nothing happens at all´ without you. For us, communication is not just a slogan, but means a constant exchange of relevant information.

Production

Even while your wastewater treatment plant is in production with us, the PRO team is in charge of your project and is always on duty for your wastewater treatment plant - to check the production deadlines, for quality control, if short-term changes should occur...

Installation and commissioning

Once your wastewater treatment plant has been completed and put through its paces, the installation, test phase and commissioning of the plant follows. And our specialists from the PRO team are still relentlessly close to you...

The control centre of the AQUAMAX ® PRO XXL systems

No AQUAMAX ® PRO XXL is like another; each system is designed according to individual requirements, needs and conditions, each system is designed with individual tank sizes and geometries. Of course, the same individuality also applies to the intelligence of the system: the control centre.

The classic AQUAMAX ® PRO XXL control system controls the system fully automatically. This system can be equipped with various additional functions according to the customer's wishes. For example, various operating states can be checked and adjusted remotely far away from the system, a switch cabinet heater can protect electronic components from cold and moisture, or a power failure monitor can signal power failures that could endanger operation.

Core components of the AQUAMAX ® PRO XLA(M) series

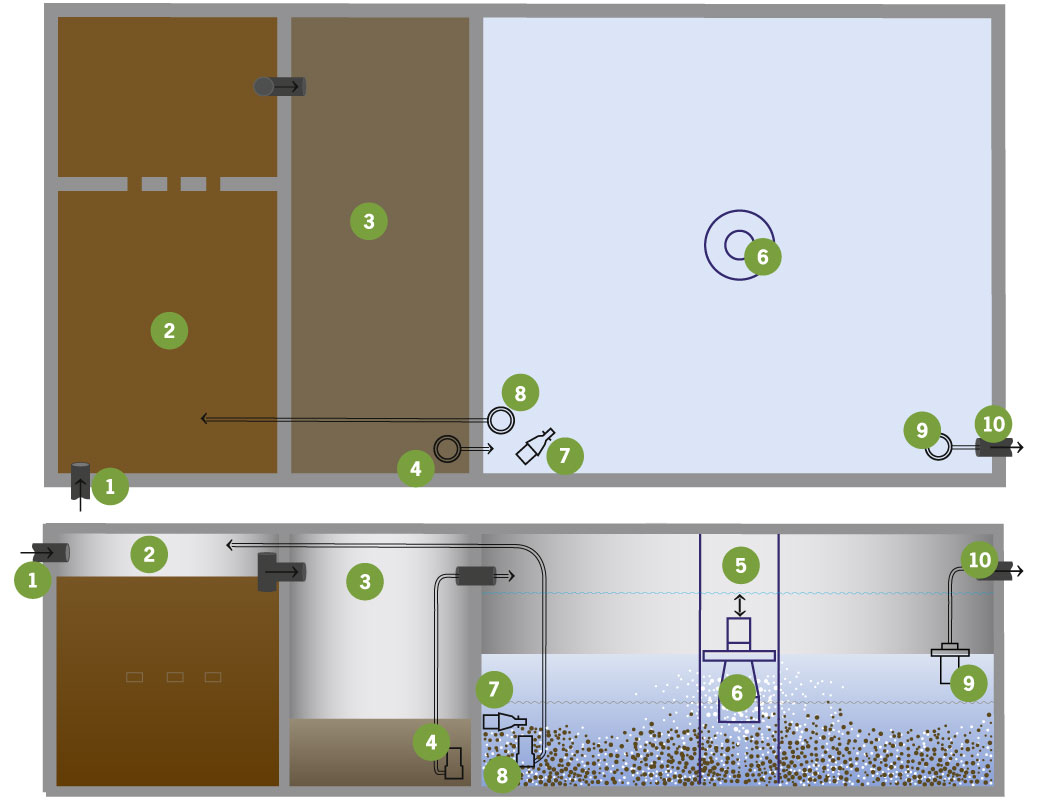

A surface aerator is used to supply the wastewater with sufficient oxygen for targeted carbon degradation and nitrification. The surface aerator is floating and adapts to the changing water level at any time. This ensures the best possible oxygen input performance at every filling level of the SBR tank. A further advantage of surface aeration is the very easy maintenance work, which can be carried out without shutting down the SBR tank.

After completion of the actual waste water treatment and completion of the sedimentation phase, the clear water is discharged from the clear water zone of the SBR tank by means of a clear water pump decanter. By maintaining a safety zone between the clear water and activated sludge zones, the removal of activated sludge is reliably prevented.

In wastewater treatment plants designed for denitrification (XLAM version), the SBR tank is additionally equipped with s mixer, which enables intensive mixing without oxygen supply of the tank contents to form an anoxic environment for denitrification. The mixer is attached to the tank side. It can be lifted via the installed guide system with the aid of a lifting bracket and brought back into the operating position.

The individual process engineering processes of the entire wastewater treatment plant are controlled via a central control panel. Depending on filling level and time, all process steps and phases of the cleaning process take place in the central control unit according to a specified program. If a fault occurs in one of the units, the fault is automatically displayed. Depending on the priority of the fault, the operation of the wastewater treatment plant is continued in emergency mode or the wastewater treatment plant is shut down until the fault is repaired. This procedure serves to prevent malfunctions which could possibly cause damage to the equipment or, in the worst case, lead to an unwanted discharge of untreated wastewater.